04

2023

-

04

The concept of precision resistors

Category:

【Summary】

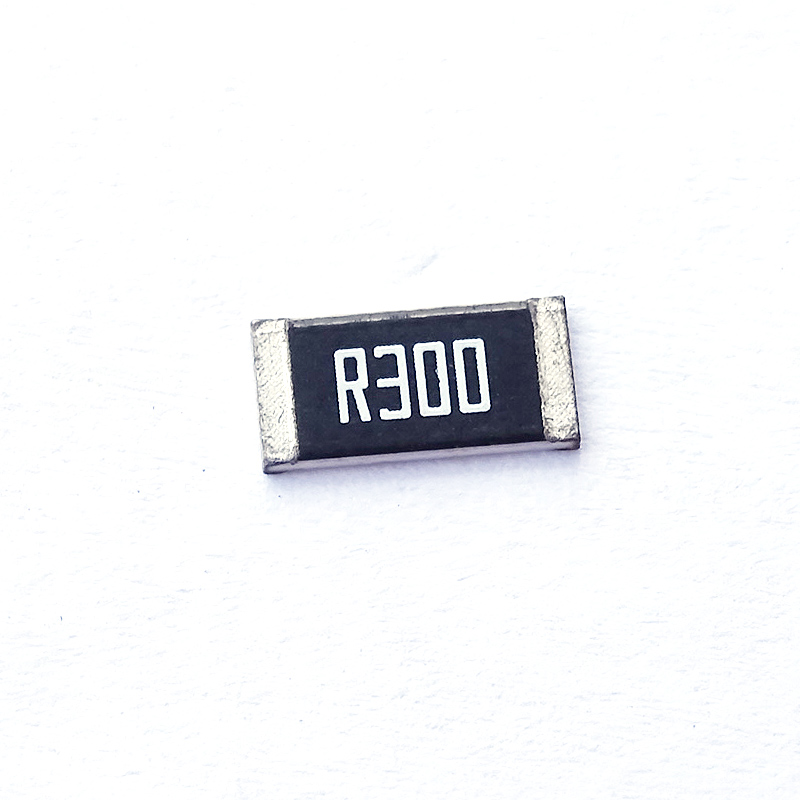

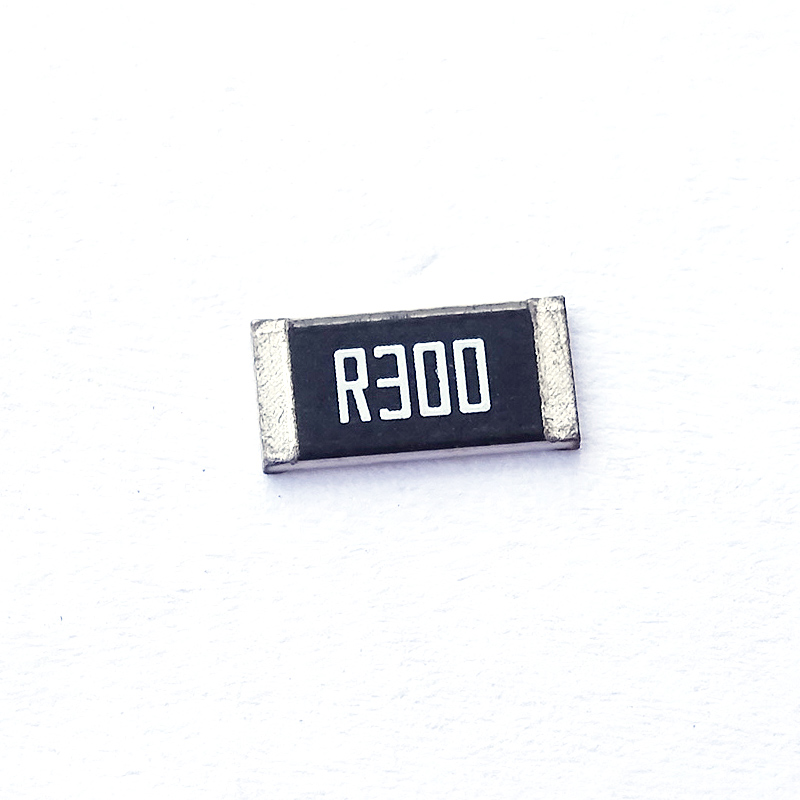

The concept of precision resistance refers to a resistor whose resistance value error, thermal stability, and distribution parameters meet certain standards. For resistors with a resistance value above 1 Ω and a resistance error within ± 0.5% compared to the marked resistance value, they can be called precision resistors. For higher precision resistors, they can achieve an accuracy of 0.01%, which is what electronic engineers call one thousandth accuracy. These types of resistors are generally thin film resistors, and resistors made of this material can generally meet the production process requirements. The precision of ordinary series resistors with resistance values above 1 Ω is above ± 5%. The most common type of resistor on electronic products is a 5% precision resistor, which is not within the precision resistance range. A resistor with a resistance value below 1 Ω can generally achieve a precision of ± 1%, which is considered a precision resistor. Because the resistance base is very small, even with a 1% error, the actual resistance error is already very small. Higher precision can be achieved within ± 0.5%, but the process requirements and technical requirements are high.

Classification of precision resistors: Precision resistors are classified by material, including metal film precision resistors, wire wound precision resistors, and metal foil precision resistors. The precision of metal film precision resistors is relatively high, but the resistance temperature coefficient and distribution parameter indicators are slightly lower; The resistance accuracy and temperature coefficient index of wire wound precision resistors are very high, but the distribution parameter index is relatively low; The precision, resistance temperature coefficient, and distribution parameters of metal foil precision resistors are all very high: the accuracy can reach 10-6, and the temperature coefficient can reach ± 0.3&TImes; 10-6/℃, distributed capacitance can be less than 0.5pF, and distributed inductance can be less than 0.1 μ H。 Due to the fact that the prices of the three types of precision resistors mentioned above increase with performance, they should be reasonably selected according to actual situations in application. For example, in DC or low frequency AC circuits, it is generally only necessary to choose wire wound precision resistors or metal film precision resistors, and there is no need to choose expensive metal foil precision resistors. The main body of metal film precision resistors is usually cylindrical; There are several types of wire wound precision resistors, including cylindrical, flat cylindrical, and rectangular frame shapes; Metal foil precision resistors are often square or sheet shaped. When the number of turns of wire wound precision resistors is large, non-inductive winding method is often used. The number of turns of forward winding and reverse winding is the same to minimize the distributed inductance. The rectangular frame shaped wire wound precision resistor is usually customized by equipment manufacturers according to their needs and is commonly used in instruments and meters. Once the precision resistance of the rectangular frame shaped wire wound in the instrument is damaged, a new alloy resistance wire with the same material, diameter, and length as the original resistance alloy wire can be uniformly wound on the original frame instead. If the original rectangular frame shaped wire wound precision resistor only has a damaged surface insulation layer, simply remove the original resistor wire from the frame, re dip it in paint, and then air dry it before rewinding it onto the original rectangular frame.

The characteristics of precision resistors require resistors that meet certain standards in terms of resistance error, thermal stability, and distribution parameters.

Related news

Milliohm Exhibition will showcase its self-developed core power resistor solutions at the 16th Asian Power Technology Development Forum on December 6th. Milliohm Exhibition 's booth is located at No. A18 on the 3rd floor of the venue. During the event, we will discuss technological innovations with industry elites from around the world and explore new opportunities for industrial development.

MORE +On November 26, 2025, the two-day 7th Gaishi Automotive Supply Chain Conference came to a successful conclusion in Shanghai. With its excellent product performance and wide application prospects, the milliohm electronic Vehicle Specification Diverter attracted much attention and became a focal exhibit on site.

MORE +On the afternoon of November 21st, Milliohm Electronics, along with several other enterprises in the Guanlan Jinxiu Science Park, participated in the park's "2025 Second Half Year Fire Emergency Drill". This drill combined theory with practical operation, covering the core aspects of fire response throughout the entire process, effectively strengthening the fire safety awareness and emergency response capabilities of all employees.

MORE +The 6th Automotive High Voltage and Drive System Conference 2025, which was held from November 19th to 20th, has come to a successful conclusion. Currently, the exhibits have been packed, and the exhibition team is about to return to Shenzhen. At the exhibition site, Milliohm Electronic automotive-grade resistor solutions received positive feedback for their core advantages, including ultra-high precision, ultra-low resistance, low temperature system, and extremely low thermoelectric potential, attracting many industry professionals to stop and inquire.

MORE +Contact us

Copyright © 2022 Shenzhen Milliohm Electronic Co.,Ltd Powered by www.300.cn Shenzhen SEO Business license